-

General questions

-

Vehicle Type Approval

-

Why do some products come with a Vehicle Type Approval?

Vehicle Type Approval in progress

Vehicle Type Approval in progress Available Vehicle Type Approval

Available Vehicle Type Approval

Using vehicle accessories while driving on the road sometimes requires a Vehicle Type Approval. With regards to our catalog, this mainly relates to all bar risers, shift bars and mounts, mirror extensions, foot pegs, and centerstands. For these products, we apply for Vehicle Type Approval from the Federal Motor Transport Authority in advance - as far in advance as possible so that we can ensure a good rapport between user benefits and installation costs. As such, our Vehicle Type Approvals are continuously being extended; current status is provided as a symbol on the product in the online shop.

If there is no Vehicle Type Approval available, it's often possible to have accessories certified by TÜV or Dekra. For this reason, we make our Vehicle Type Approval documents as well as, upon request, material appraisals available to you.

-

Where can I find the Vehicle Type Approval stamp on my bar riser/shift bar?

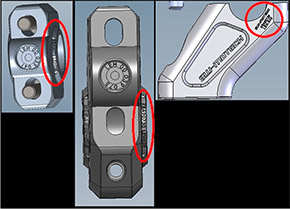

JDepending on which product you use, the Vehicle Type Approval stamp is located in different places. The illustration shows examples of where the Federal Motor Transport Authority number may be printed. For older products, the identifier may not have been stamped, but was glued with a special film.

-

Why do you specify a speed limit and permissible total load for many luggage systems?

For many luggage systems, we specify a speed limit of 130 km/h and a maximum permissible total load. There are technical, legal and driving performance-related reasons for this:

The specified load limit for our luggage is determined on one hand by manufacturer information regarding load capacity and resilience of the frame tail, on the other hand, by how many mounting points can be used.

In Germany, moreover, partial liability of all parties involved is applicable in the case of accidents involving a speed of more than 130 km/h. For this reason, we have included this speed limit in our product notes.

In any case, do keep in mind that the handling attributes of your motorcycle will change as a result of adding luggage solutions. The changes increase with higher speed and higher loads - regardless of whether the function of our luggage solutions is provided under these conditions.

-

Why do some products come with a Vehicle Type Approval?

-

Screws: steel vs. stainless steel

-

Why do you generally not use stainless steel screws?

The simple reason behind this is that stainless steel screws offer a maximum strength class of 8.8, but in many cases we need a strength class of 10.9 or higher. In addition, stainless steel screws only remain stainless as long as they are processed together with other precious metals. As soon as a stainless steel screw is used in conjunction with normal ST37 steel, it may also start to rust. For these reasons, we usually use steel screws that are surface-treated to protect against corrosion. Due to the high customer demand, we plan on using stainless steel screws for some components in the future, even if they offer no concrete technical advantage.

-

Why do you generally not use stainless steel screws?

-

Materials

-

1680D Ballistic Nylon

This tough polyamide fabric was formerly used in the manufacture of flak jackets. Polyamide fibers are very abrasion resistant and durable. At the same time they are light and elastic. 1680D denotes the yarn weight: it corresponds to 1680 grams per 9000 meters of yarn. The abbreviation D stands for the unit of measurement denier. It originates from the French silk industry of the 19th century and is still used today for calculating the yarn weight of ladies' tights. For comparison, opaque tights have a value of 50 D.

-

ABS plastic

ABS stands for Acrylonitrile Butadiene Styrene: This plastic is very light and yet break-resistant. The surface is scratch and impact resistant. A well-known example of the durability of ABS is the LEGO brick. We use ABS for the production of our side cases of the URBAN ABS and AERO ABS series.

-

EVA plastic

EVA stands for ethylene vinyl acetate. This firm plastic foam is very easy to press into molds and yet remains elastic. The material is highly resistant to abrasion, tearing and impact and is suitable for the production of shoe soles, cable sheathing and for ice cube containers. We use EVA to give shape to the lids and sidewalls of many PRO tank bags and tail bags.

-

Hypalon

The chemical name of this material is chlorosulfate polyethylene or CSM for short). The name 'Hypalon' is a trademark designation of the DuPont company. Although DuPont has not manufactured Hypalon since 2010, the name has persisted as a designation for CSM. That is why we continue to use this term for the material from which the MOLLE attachments of our tank bags and tail bags are made.

Hypalon is characterized by high tensile strength as well as high UV, temperature and aging resistance. The MOLLE attachments made of Hypalon are very stable and are very well suited for the attachment of additional bags with loops and adapters such as the T-Lock. Because it is very non-slip and grippy even when wet, CSM is often used for inflatable boat construction. -

PA plastic

PA stands for polyamide. We use polyamide fibers to make the fabrics for our bags. Polyamide fibers are very abrasion resistant and durable. They are also elastic and lightweight. That's why we also make most of the webbing for our bags from polyamide fibers. Tennis racket strings and fishing lines are also made from this durable material.

In combination with glass fibers, we use polyamide for the production of our tank rings and crash pads. The material, called PA6 GF30, is a plastic with a glass fiber content of 30 percent. Fiber composites are also used in the manufacture of dowels and unbreakable household items such as bowls or ladles. -

PES plastic

PES stands for polyester. The material is highly UV and weather resistant, abrasion and tear resistant, and at the same time soft. In combination with a coating of PVC it is completely waterproof. We use polyester fabric with a thickness of 500D for our drybags. Truck tarpaulins are made of 1000D fabric. Polyester became famous in the 1970's as a wrinkle and iron resistant fabric for shirts and suits, which were then presentable, but their owners also needed a lot of deodorant because of the fabric's lack of breathability.

-

PVC coating

PVC stands for polyvinyl chloride. The material is very light and weather resistant and flexible. The coating makes the polyester fabric completely waterproof. We use PVC coating for our waterproof bags from the Drybag series. The material is very versatile: it is used to make records, sewage pipes and flooring, among other things.

-

PU coating

PU stands for polyurethane. It is highly water-repellent, abrasion- and kink-resistant and was developed in the 1930s by Otto Bayer in Leverkusen. The versatile PU is used to make cleaning sponges, dashboards, bowling balls, condoms and coatings.

In liquid form, the polyurethane is applied to textiles, for example in outdoor clothing. This can make fabrics highly water-repellent or completely waterproof, depending on the amount applied. At the same time, the coated fabric remains flexible. We use the single-coated / double-coated PU coating for the inside of our Ballistic Nylon bags, so that the contents are well protected from moisture penetration. Our waterproof inner bags are coated on the inside with PU and the seams are taped. -

TPE plastic

TPE stands for thermoplastic elastomers. It is soft like rubber and can be molded into solid shapes when heat is applied. Instrument panels in vehicle construction, cable sheathing and yoga mats are made of TPE. Because of its strong damping properties, we use TPE in combination with glass-fiber-reinforced polyamide for our axle crash pads.

-

TPU plastic

TPU stands for thermoplastic polyurethane. The material is highly resistant to abrasion and tearing and is resistant to oils, greases and many solvents. Therefore, it is used in vehicle construction for seals and piping. Shoe soles and cell phone covers are also made of TPU. SW-MOTECH manufactures the waterproof tank bags from this material, because the individual bag parts can be welded together. This avoids damage to the material by needle punctures, which would occur during sewing and would be possible entry points for moisture.

-

1680D Ballistic Nylon

-

Shipping costs

-

How high are the shipping costs?

You can find everything on the topic of shipping here.

-

How high are the shipping costs?

-

International orders online

-

Can I also order directly from the online shop if I live outside of Germany?

Please keep in mind that our online store only accepts direct orders from Andorra, Belgium, Bosnia-Herzegovina, Bulgaria, Denmark, Germany, Estonia, Finland, France, Greece, Greenland, United Kingdom, Ireland, Italy, Croatia, Croatia, Latvia, Liechtenstein , Lithuania, Luxembourg, Malta, Macedonia, Monaco, Netherlands, Austria, Poland, Portugal, Romania, San Marino, Sweden, Slovakia, Slovenia, Spain, Czech Republic, Hungary, Cyprus. Customers from other countries can use the multilingual shop for the product research, but in order to place an actual order we ask you to contact our partners in your respective country.It is possible for the final price for an international delivery depending on tax and/or customs regulations differs from the amount displayed in the online store for delivery to Germany. Delivery times may vary as well.

-

Can I also order directly from the online shop if I live outside of Germany?

-

Vehicle not in model list

-

Where is my vehicle in the model list?

For our products, we only list approved models that have been tested by us. Due to the large number of models and partly country-specific motorcycle models, we cannot test our products on every model. However, many non-vehicle-specific products - such as tail bags, tank bags or GPS universal holders - fit on a large number of other vehicles. However, we cannot make specific product recommendations. In this case, in order to find a suitable solution for your motorcycle, we recommend visiting one of our dealers in your area.

-

Where is my vehicle in the model list?

-

Incorrect production year

-

A product for my vehicle is listed as being from year X, but the model was sold later. Is there an error in the model mapping?

For our year of construction, we always follow the release data for the motorcycle models provided by the Federal Motor Transport Authority. Sometimes, it may happen that manufacturers add new motorcycle models well before the launch listed by the Federal Motor Transport Authority; as such, we have different year of construction data than the actual sales period.

If you have any doubts regarding correct model assignment due to the year of construction, please check the type designation likewise indicated by us and compare it to the one on your vehicle registration certificate.

-

A product for my vehicle is listed as being from year X, but the model was sold later. Is there an error in the model mapping?

-

Find spare parts in the shop

-

How do I find the right spare part for my product?

- Search for the item for which you need a spare part in the online shop

- If you go to the item page, you'll find a link entitled "mounting instructions (PDF)" below the item description.

- Open the mounting instructions and note the item number and quantity of the spare parts required from the overview display

- Send us an email at info@sw-motech.com and tell us the part number(s) you want. Our customer service will then promptly send you an offer.

With regards to the delivery time, please keep in mind that we don't have all individual parts in stock and that they may have to be produced first.

Unfortunately, due to the large number of products and components listed in our shop, we cannot directly offer all spare parts. Accessories and spare parts for bags and tank bags can be found in the corresponding section under luggage systems.

For almost all other spare parts there is the following option:

-

How do I find the right spare part for my product?

-

Vehicle Type Approval

-

Luggage

-

Tank bags & Tank rings

-

What is the difference between the ION, EVO and PRO tank bags?

Our ION tank bag series is an inexpensive alternative to premium tank bags from the PRO and EVO series. In order to be able to offer high-quality products at an attractive, entry-level price, some features are only incorporated into the ION series in a modified form. This can be seen, for example, in the forgoing of a GPS holder on the front of the tank bag and the use of lightweight 600D polyester instead of the reinforced 1680D ballistic nylon as the outer material.

-

Is it possible to individually re-order the pull strap for PRO and EVO tank bags?

Yes, pull straps are available separately for all tank bags from the PRO and EVO series on request through our customer service.

-

What is the difference between the PRO, EVO and ION tank rings?

All tank rings from all three PRO, EVO and ION series are equipped with the comfortable QUICK-LOCK mechanism, which makes it easy to attach the tank bags. With the PRO series, the Fidlock technology magnetic guide has also been installed, which makes attaching PRO tank bags even simpler. Thanks to its simple yet solid construction, the ION tank ring guarantees a secure hold when travelling around the globe, even under the most adverse conditions. Note: tank bags only fit onto tank rings from their corresponding series.

-

I would like to convert to an electric tank ring. What do I need for that?

Conversion is possible for the QUICK-LOCK EVO version. The QUICK-LOCK EVO version of the tank ring system (TRT.xx.640.xxxxx) only requires the purchase of an electric EVO top ring. With this you also get the required electrical conversion kit for your QUICK-LOCK EVO subring.

-

I can't measure any current on my electrical tank ring along the contacts. Is the plug defective?

- Tank bag not set correctly -> Check position and anchor again

- Cable not properly connected -> Check wiring and connect correctly

- Gold contacts melted on the top ring -> Visual inspection for holes on subring contacts

- Magnetic switch defective -> Check the switch using a strong magnet. You should be able to hear a clack.

Thanks to the use of a magnetic circuit, the contacts on the tank ring are only supplied with power when the tank bag top ring is attached. If there is no current, the following steps can help discover the cause:

-

What does 1680D Ballistic Nylon mean and what are the advantages of using this material?

Originally 1680D Ballistic Nylon was developed for the production of flak jackets during World War II, hence the name Ballistic. The material stands out due to its high durability and abrasion resistance and is therefore used in the safety, outdoor and bag sector, among other things. For this reason, we use 1680D Ballistic Nylon in QUICK-LOCK EVO tank bags and many tail bags, which is usually reinforced with other plastics or foams to provide a stable shape. In a complex production, high-quality composite products are created, which are perfectly suitable for use on motorcycles.

-

What does MOLLE mean?

The abbreviation MOLLE stands for MOdular Lightweight Load-carrying Equipment and refers to a military frame system for attaching bags and equipment. SW-MOTECH has made use of this impressive level of flexibility and has added MOLLE extensions to the surface of soft luggage products. Smartphone and tablet holders, as well as additional bags, can be securely strapped to the robust grid pattern.

-

I would like to order your TRT.00.640.12602/B tank ring with Keyless Ride for my BMW R 1200 GS LC, will this fit on my bike?

- EVO tank ring -> TRT.00.787.30600/B

- EVO tank ring -> TRT.00.640.30601/B

- ION tank ring -> TRT.00.475.30601/B

There are specially adapted tank ring variants for the BMW R 1200 GS LC and the BMW R 1200 GS LC Adventure Keyless Ride from the year 2014 :

Other tank rings do not fit on the two Keyless models mentioned above. -

Why is my tank bag so hard to lock?

If a EVO or ION tank bag can only be latched onto the tank ring with heavy pressure, this is usually due to the fact that it has been incorrectly fastened; if the holes on the EVA base plate of the tank bag are not properly positioned, the top ring may warp when tightening the screws during assembly. As a result, the pressure is improperly distributed and there isn't enough force on the top ring - i.e. the tank bag doesn't correctly match the tank ring. Please check the hole pattern with the drilling template; if it's not an exact fit, usually a minor correction of the mounting hole can help.

-

My tank bag is too close to the tank after assembly. What can be done?

EVO tank bags have an unpainted, laminated bottom. However, the mounting system is designed so that the tank bag "floats" on the tank ring above the tank - there should be no contact between the bag and your tank. On some motorcycle models, the tank bag is nonetheless on the tank, even if correctly installed. To tackle this issue, we've designed the drilling template so that it can be used as a spacer: simply screw in the template between the top ring and the tank bag during assembly. As a result, the distance between the bag and tank increases significantly.

-

Does the PRO tank bag fit on the EVO tank ring? (and vice versa)

No. PRO series tank bags cannot be combined with EVO tank rings nor vice versa.

-

Are ION tank bags also equipped with the EVO tank ring?

ION tank bags only come with the QUICK-LOCK system. However, the ION top ring attached to the bottom of the tank bag can be replaced with a EVO top ring . As such, the ION tank bag can be locked on to the EVO tank ring that fits your vehicle.

-

Can I order the PRO upper ring individually?

No, the PRO upper ring cannot be bought individually.

-

What is the difference between the ION, EVO and PRO tank bags?

-

Saddlebags (Blaze & Dakar)

-

Are BLAZE® removable support arms also available separately?

Removable support arms for BLAZE® saddlebags are only available in a set with BLAZE bags. This is due to the fact that only the correct combination of bag and model-specific support arm ensures a tight fit and prevents flapping and contact with the chain and rear wheel. In the event of damage or vehicle change, we will gladly send you an offer for a single support arm set after having received your original receipt.

-

Is it possible to have a passenger when using BLAZE® saddlebags?

We're not aware of any legal restrictions regarding the use of BLAZE® saddlebags with a passenger. However, the seat quality for the passenger can be impacted by the Velcro® over the seat. Depending on the position of the pockets on the motorcycle, passenger legroom can also be reduced in certain cases.

-

I would like to buy BLAZE® saddlebags for my motorcycle, but my model/production year is not listed?

The mounting kits for BLAZE® saddlebags are developed and manufactured to be bike-specific. As a rule, it is therefore not possible to fit them on to other motorcycle models or the same model from a different year of manufacture, as this deviates from our recommendations. For safety reasons, we strongly advise you to comply with SW-MOTECH model information when purchasing BLAZE® saddlebags.

-

How do I avoid contact between the bench paint and my BLAZE® saddlebags?

Depending on the motorcycle model, the main retaining strap for BLAZE® saddlebags sometimes rests not only on the bench, but also on the seat trim. In this case, all BLAZE® saddlebags come with paint protection film. First, thoroughly clean the surface and then install the film along the areas of the seat that can come into contact with the retaining strap. Please note that protruding or sharp-edged cladding elements should be taped in several layers for reliable protection.

-

Are DAKAR removable support arms also available separately?

Removable support arms for DAKAR saddlebags are only available in a set with DAKAR bags. This is due to the fact that only the correct combination of bag and model-specific support arm ensures a tight fit and prevents flapping and contact with the chain and rear wheel. In the event of damage or vehicle change, we will gladly send you an offer for a single support arm set after having received your original receipt.

-

I would like to buy DAKAR saddlebags for my motorcycle, but my model/production year is not listed?

The mounting kits for DAKAR saddlebags are developed and manufactured to be bike-specific. As a rule, it is therefore not possible to fit them on to other motorcycle models or the same model from a different year of manufacture, as this deviates from our recommendations.

-

Are BLAZE® removable support arms also available separately?

-

Side cases

-

What is the difference between the AERO ABS and URBAN ABS side cases?

The AERO ABS side case is bigger, heavier and offers more volume. It holds 25 liters. It can be mounted on both PRO and EVO side carriers. The URBAN ABS side case, on the other hand, only fits on the SLC carrier and holds 16.5 liters.

-

Is it possible to mount AERO ABS side cases on the old QUICK-LOCK carriers?

Unfortunately, AERO adapter kits only fit side carriers from the PRO and EVO series.

-

Can I fit a helmet in your aluminum cases?

A helmet can be stored in the TRAX top cases (TRAX ADV/ION/EVO). Unfortunately, helmets cannot fit in the side cases.

-

Are TRAX aluminum cases waterproof?

TRAX ADV and TRAX ION aluminum cases are waterproof and dustproof. TRAX EVO aluminum cases are splash-proof.

-

Can aluminum cases also be used on original GIVI carriers?

Our case systems are designed for openness - after all, we don't want to force you to immediately buy the matching carrier when you buy a new case. That's why we offer adapter sets for our TRAX ADV/ION/EVO cases KFT.00.152.10700/B for GIVI carriers.

-

Are SW-MOTECH aluminum cases compatible with the original BMW R1200 GS Adventure carriers?

We offer two adapter sets for the BMW R1200GS Adventure for our TRAX ADV and TRAX ION cases. As such, the side cases can be easily mounted on to the original carrier:

KFT.00.152.10900/S for BMW R 1200 GS LC Adv from BJ 2013

-

Are the locks included in delivery with TRAX ADV/ION/EVO cases?

As a rule, since there are numerous case combination options and we always want to offer you a single-key locking system, locks must be ordered separately. Depending on the number of cases, we recommend the following lock sets, each containing a lock cylinder, keys and retaining plates:

1 case or 1 top case: ALK.00.165.16503

2 cases and 1 top case: ALK.00.165.16303

Best buy: the appropriate lock cylinder set is already included with the bike-specific case system.

-

Can I re-order spare keys for the TRAX side case lock cylinder?

Unfortunately it is not possible to order or make a replacement key with the key code. However, complete, identical locks for TRAX EVO and TRAX ADV aluminum cases are for sale under the following product numbers in the online shop:

2 locks and 2 keys: Prod. No. ALK.00.165.16502

6 locks and 2 keys: Prod. No. ALK.00.165.16303

-

Can the keys for the Alubox lock cylinder be combined with QUICK-LOCK anti-theft protection?

Different lock systems are used for the QUICK-LOCK anti-theft protection and the ALU-BOX lock cylinders. We are therefore unable to offer identical solutions for cases and QUICK-LOCK EVO carriers.

-

Which accessories are available for the TRAX side case?

We offer high-quality accessories as a supplement to our TRAX side cases for comfortable luggage handling.

Product no. Product name TRAX ADV TRAX EVO BC.ALK.00.732.10000/B Side case inner bag Yes Yes BC.ALK.00.732.10100/B Side case lid inner bag Yes No BC.ALK.00.732.10200/B Side case expansion pocket Yes not recommended BC.ALK.00.732.10400/B Side case lid net M Yes No BC.ALK.00.732.10500/B Side case lid net L Yes No BC.ALK.00.732.10300/B Top case inner bag Yes Yes BC.ALK.00.732.10600/B Top case lid net Yes No

-

What is the difference between the AERO ABS and URBAN ABS side cases?

-

Side carrier

-

What adapter kits are there for PRO side carriers?

Adapter kits for SW-MOTECH products

KFT.00.152.35100

For TRAX aluminum case/Nanuk side case

KFT.00.152.35200

For AERO ABS side case

SYS.00.001.13000

For SysBag 15/30 bag with adapter plateAdapter kits for products from other manufacturers

KFT.00.152.35400

For Givi/Kappa with Monokey

KFT.00.152.35600

For Krauser with K-Wing and Hepco & Becker with C-Bow Wing/C-Bow not included

KFT.00.152.35700

Shad I: for SH26, SH29, SH32, SH33, SH37, SH39, SH40, SH40CA, SH42, SH43, SH45, SH46

KFT.00.152.35800

Shad II: for SH48, SH49, SH50, SH58x

KFT.00.152.35900

For RotopaX RotopaX mounting not included -

How much weight can the side carriers hold?

The weight of the carrier and the capacity varies by motorcycle. You can always get the exact details from the respective PDF attachment instructions. These can be found under the product description. In addition, there is a sticker on each side carrier with a note on the maximum cargo capacity.

-

Is anti-theft protection included in delivery with the PRO/EVO side carrier?

Anti-theft protection is only included in delivery with the (TRAX® and AERO) case systems. Anti-theft protection can be ordered separately for the individual PRO QLS.00.095.10000/B and QLS.00.046.10100/B EVO side carriers.

-

Can carrier adapter sets from the first QUICK-LOCK generation also be used for EVO side carriers (or vice versa)?

Since the adapter sets for the EVO side carriers are different from those of the first gen side carrier, we regret that they cannot be used together.

-

Do side carriers fit on machines with custom-built tails or exhaust?

Since we can only ever test the motorcycles in their original condition, it is not possible for us to take potential modifications or accessories into account. Experience has shown, however, that mounting the carrier when using another licence plate holder is possible. However, the crossbar must be installed in order to ensure stability.

-

Can I continue to use the old adapter kits from the EVO side carrier for the PRO side carrier?

No, see graphic.

Adapter kit for PRO side carrier

For TRAX ADV/ION/EVO, NANUKMounting of 2 side casesKFT.00.152.35100

Adapter kit for PRO side carrier

For AERO ABS. Mounting of 2 side casesKFT.00.152.35200

Adapter kit for SysBag

For 1 adapter plate for SysBag10/15/30. For PRO side carrier, EVO carrier. For STREET-RACK, ADVENTURE-RACK, STEEL-RACK and ALU-RACK.SYS.00.001.13000

Adapter kit for PRO side carrier

For Givi/Kappa with Monokey. Mounting of 2 side carriers.KFT.00.152.35400

Adapter kit for PRO side carrier

For Krauser K-Wing/Hepco &Becker C-Bow. K-Wing/C-Bow not included. Mounting of 2 side cases.KFT.00.152.35600

Adapter kit for PRO side carrier

Shad 1. For SH26, SH29, SH32,SH33, SH37, SH39, SH40, SH40CA, SH42, SH43, SH45, SH46.Mounting of 2 side cases.KFT.00.152.35700

Adapterkit für PRO Seitenträger

Shad 2. Für SH48, SH49, SH50,SH58x. Montage von 2 Seitenkoffern.KFT.00.152.35800

Adapter kit for PRO side carrier

For RotopaX. RotopaX mounting included. Mounting of 1 canister.KFT.00.152.35900

-

Is it also possible to mount AERO ABS side cases onto the first gen QUICK-LOCK side carriers?

Unfortunately, the AERO adapter sets only fit EVO side carriers.

-

Which side cases/side bags can I attach to my SLC side carrier?

URBAN ABS side case

The aerodynamic URBAN ABS side cases cut a good figure on sporty street bikes and naked bikes. The plastic cases combine light weight with high resilience.

SysBag 10/15 with adapter plate

The versatile SysBag series with bags in three sizes offers the perfect luggage solution for every motorbike. The SysBag 10/15 with adapter plate can be securely fastened to SLC side carriers with a single click.

Legend Gear side bag LC1/LC2

Designed with a classic look exclusively for motorbikes, the Legend Gear soft luggage made of canvas and Napalon imitation leather captivates with its fashionable retro look. The side bags are also available in a Black Edition.

-

What adapter kits are there for PRO side carriers?

-

Luggage racks

-

In what ways are the ALU-RACK and STEEL-RACK different?

The ALU-RACK's QUICK-LOCK system gives you the option to switch between adapter plates for different top case systems within seconds. Furthermore, we offer a large luggage bridge with quick-release fastener for simple and secure transport of tail bags. The use of QUICK-LOCK EVO tank bags on the ALU-RACK is also possible via quick-release fastener adapter. Should the adapter not be needed, it can be removed in no time. The elegant tail carriers are designed to be bike-specific, enabling simple mounting and the best interaction with the motorcycle design.

The STEEL-RACK is meant for price-conscious shoppers that do not use different luggage systems on the tail. A STEEL-RACK adapter set - available, for example, for TRAX aluminum cases and T-RaY top cases - typically remains fixed on the STEEL-RACK and therefore on the motorcycle. The attachment of the STEEL RACK is - similar to that of the ALU-RACK - tailored to the motorcycle model. However, in most cases the STEEL-RACK is somewhat more widely used. -

Can you use the STREET-RACK adapter plates on the ADVENTURE-RACK?

Yes, you can mount (GPT.00.152.35000/B) the STREET RACK adapter plates on the ADVENTURE-RACK with the following items

-

What is the difference between the ALU-RACK and STREET-RACK?

The STREET-RACK is the redesigned and newer version of the ALU-RACK. It is even more sturdy and tailored even more to the sleek shape of sporty motorcycles. The newly developed adapter plate can be mounted to the STREET-RACK without tools and just one hand movement. The adapter plate is simply slid onto the rack and securely locked using the rotating cam latch. However, this adapter plate cannot be mounted on the ALU-RACK. Nor can the ALU-RACK adapter plate be mounted on the STREET-RACK.

-

Which SysBag adapter plate fits on which rack?

Overview of adapter kits for racks:

ADVENTURE-RACK STREET-RACK ALU-RACK STEEL-RACK SysBag 10 with adapter plate X GPT.00.152.50000/B, SYS.00.001.13000 X X SysBag 15 with adapter plate ✔ GPT.00.152.50000/B X ✔ SysBag 30 with adapter plate ✔ GPT.00.152.50000/B GPT.00.152.450 ✔

-

In what ways are the ALU-RACK and STEEL-RACK different?

-

Legend Gear

-

Does the canvas material remain water resistant; rather, do I need to follow particular care instructions for the bags?

First remove dust and incrustations with a damp textile brush. Stubborn deposits can be removed with a soft cloth and warm soap solution. Do not use any harsh cleaning agents, utensils or a pressure washer! Then rinse with clean water.

Let the product air-dry (not in direct sunlight) for 24 hours before using. To protect the natural fibers from weather conditions, we recommend impregnating the cotton textile surface of the product at regular intervals or after intensive cleaning with commercially available wax waterproofing (such as Fjällräven Greenland wax). -

What is the load capacity of the Legend Gear side bags LC1/LC2 and LS1/LS2

The maximum load capacity of the bags is 5kg per side, furthermore the maximum load capacity of the motorcycle manufacturer applies. Warning: check the proper position of the product before the start of a journey and at every break (every 200km)!

-

Will the Legend Gear saddlebag holder SLS and the saddlebags LS1 / LS2 fit on my motorcycle?

The saddlebag holder SLS and the saddle bags LS1 / LS2 are suitable for a variety of motorcycles with seats with a second seat and also for modifications. In our shop we only recommend the SLS saddlebag holder for motorcycles on which we've tested the mounting and can guarantee a secure hold.

-

I would like to have the Legend Gear carrier for my motorcycle, unfortunately the carrier isn't listed for my model.

It is possible to design a customized model for your motorcycle with our Legend Gear mount for side bags; (HTA.00.401.15000) in this case, you will have to craft the attachment points for the mount on your own. The Legend Gear mounts for side bags are not painted, SW-MOTECH does not accept any liability (this exclusion of liability also applies to mounted side bags). It is imperative that you heed all information in the Legend Gear side bag mounting instructions prior to planning the construction. Note the country-specific regulations for registration/operation of your motorcycle and applicable TÜV regulations, respectively.

-

Does the canvas material remain water resistant; rather, do I need to follow particular care instructions for the bags?

-

Tank bags & Tank rings

-

Safety

-

Stands

-

After mounting a SW-MOTECH centerstand, the vehicle can be jacked up and stands very straight. Is it supposed to be like this?

We choose the best possible angle when developing our centerstands in order to easily jack up the vehicle and ensure secure footing. Unfortunately, it's not always possible for us to choose the perfect angle for the best leverage, usually due to design constraints on the part of the vehicle manufacturer.

The suitability of our centerstands is in principle tested by the TÜV and documented by Vehicle Type Approval 30365*14 and 30910*03. It simulates several gradients and slopes. In any case, we ask you to first check whether the product was installed exactly according to the mounting instructions. -

What is the load capacity of the lift stands in kilograms?

Our CE-approved Enduro and Supermoto stands have a maximum lifting capacity of 180 kg.

-

After mounting a SW-MOTECH centerstand, the vehicle can be jacked up and stands very straight. Is it supposed to be like this?

-

Additional headlights

-

Can SW-MOTECH lights be mounted upright and suspended?

The Fog lights and High beams have mounting points on all four sides of the case, but due to the curvature of the reflector, only those with the SW-MOTECH logo can be mounted upwards; they can be mounted upright and hung as well.

-

Can SW-MOTECH lights be mounted upright and suspended?

-

Stands

-

Protection

-

Engine guard

-

Does the engine guard have to be removed when changing the oil on my motorcycle?

When designing the engine guard, it's usually taken into account that the customer should be able to carry out the oil change without dismantling the engine guard. For some models, this is unfortunately not possible due to the design of the vehicle.

-

Does the engine guard have to be removed when changing the oil on my motorcycle?

-

Engine guard

-

Ergonomics

-

Footrest kits

-

What are the differences between the ION and EVO footrests?

EVO footrests offer more positioning possibilities on the bike compared to ION footrests. An ingenious system with firmly interlocking teeth enables 36 individual settings.

-

Can I re-order the rubber overlay?

Yes, the rubber overlay are available separately for both series on request through our customer service.

-

How is the lowered position of the footrest kit measured?

The footrest kit can be mounted either in its original position or 15 mm lower. The measurements for the position of the tread surface include the rubber pad.

-

Do you also offer footrests for the passenger seat?

Currently we only offer our footrest kits for the front footrests. If the front and rear pegs are identical, the pegs can also be used for the passenger seat. However, this is not covered by the Vehicle Type Approval.

-

What are the differences between the ION and EVO footrests?

-

Comfort cushions

-

My comfort cushion makes hissing sounds when I sit on it. Is the pillow leaking?

Cushions have several interconnected air chambers; depending on the pressure, the air can escape from the chambers. The chambers therefore have no leaks because the air is transferred to the other chambers depending on the air pressure.

-

Can I quickly inflate seat cushions with a compressor?

No, TRAVELLER COMFORT CUSHIONS should not be inflated using a compressor or become overcrowded, since the individual air chambers may expand too far and become damaged.

-

My comfort cushion makes hissing sounds when I sit on it. Is the pillow leaking?

-

Footrest kits

-

Navigation

-

GPS mount

-

The mounting frame was not included in delivery with my GPS holder?

Please note that the retaining frame is usually clicked onto the slide-in frame and is easy to overlook, as these parts look like one part when delivered.

-

Can I still see my instruments after installing the QUICK-LOCK GPS holder?

- Available instruments on the side of the motorcycle are operational

- The most unrestricted view of the cockpit

We develop bike-specific holders that ensure:

Due to the limited space available, we are forced to make a compromise in exceptional cases in which the field of vision of the instruments may be subject to slight restrictions. Please note that we cannot make a general statement that applies to all navigation devices.

-

The mounting frame was not included in delivery with my GPS holder?

-

Bags & accessories

-

Are the hard cases offered waterproof and can I operate my smartphone through the case?

Our hard cases are splash-proof and dust-proof. The functionality of your device remains intact. Pictures/videos can be taken and of course the device can also be charged in the hardcase. Thanks to the special film, it is also possible to operate the touchpad (depending on the gloves used).

-

Is your Navi Case Pro waterproof and can I still operate my device despite the case?

Our Navi Case Pro gear bags protect hardware from splashes and dust. Due to the special foil used, it's also possible to operate the device inside the case.

-

Which motorcycle GPS devices fit on the hole pattern of the SW-MOTECH GPS holder?

The hole pattern on the mounting plate of our GPS holders - QUICK-LOCK GPS holders, Nonshock GPS holders and GPS tank bag holders - are designed to be compatible with all popular motorcycle GPS devices. An overview of corresponding models can be found in the following table. When installing other GPS devices, we offer splash-proof Navi Case Pro gear bags in different sizes.

Device Compatible with GPS holder TomTom Rider (all) yes Garmin Montana yes Garmin zumo 340 LM with adapter GPS.00.085.10000/B Garmin zumo 350 LM with adapter GPS.00.085.10000/B Garmin zumo 390 LM with adapter GPS.00.085.10000/B Garmin zumo 400 yes Garmin zumo 500 yes Garmin zumo 550 yes Garmin zumo 590 LM with adapter GPS.00.085.10000/B Garmin zumo 660 with adapter GPS.00.085.10000/B RAM hardshell yes Blaupunkt MotoPilot yes

-

Are the hard cases offered waterproof and can I operate my smartphone through the case?

-

GPS mount

-

Seat conversions

-

I am located in XY. Can I have my seat customized by SW-MOTECH?

We wish that we could offer seat customizations to all customers. Unfortunately, for logistical reasons, this is not always possible. If you are located in the following countries, we can offer your seat customization:

Germany

Austria

France

Spain

Italy -

Do you offer leather samples?

We are happy to provide a sample of our imitation leather and thread if you would like to see it before choosing your own configuration. Please contact our team at info@sw-motech.com

-

How can I keep my seat in good condition?

We recommend cleaning with a mild detergent solution. Avoid chemical cleaners. Here's a tip: S100 seat cleaner!

This can also be used with imitation leather, and it helps protect you against slipping while riding.

-

Are the customized seats waterproof?

The seams are not waterproof and it is normal for water to soak through them when they are exposed to rain, for example. Under normal temperature conditions, the seat will dry out again soon. The inner foam layer of the seat is sealed from moisture and is not affected by water ingress.

-

After customization, the gap between the tank and seat is bigger. Is this normal?

Yes, because the upholstery has been tightened to ensure that it fits perfectly and does not wrinkle, even after a long time.

-

Can you leave off the SW-MOTECH bull logo?

No, the logo is a permanent fixture and will appear on any of our customizations.

-

I have additional features (buttons, fixtures) on my seat. What will happen to them?

Any decorative elements that are sewn or glued to the original seat will be removed during the customization. Exception: The new seat includes one permanent attachment.

-

Do you also offer embroidery for the seats?

No, because embroidery would make the material less waterproof and more prone to tearing.

-

Does the upholstery have any special characteristics that I should know about?

For heavily curved seats, we build in a so-called 'relaxer searm'. This prevents the outer material from wrinkling.

Tip: Black (Velour) and Black (Rawhide) are excellent choices for seats, because they also have non-slip properties.

-

I have a gel inset in my seat. Can I still use this?

In most cases, the gel will no longer work, because it is covered by the upholstery (comfort upholstery, padding, etc.)

If you don't want to keep your gel padding, we can also replace it a foam cushion.

-

What does bi-elastic mean?

Bi-elastic is a material property of some types of imitation leather (Black Velour, Grain, Rawhide and Carbon). It means that the imitation leather can be stretched in all directions. This is why we always recommend quilting in combination with bi-elastic imitation leather.

-

What is the comfort upholstery and what does it do?

The comfort upholstery, also called spacer fabric, is a breathable, three-dimensional fabric that is also used in air-conditioned seats in the automotive industry. Please note: The comfort upholstery adds 10 mm of padding to the seat.

It offers many benefits compared to gel padding (which we never use):

Shock-absortion

Force absorption points and optimal pressure distribution

Full-surface treatment

Cold/heat insulated

Light weight

Highly UV-resistant

Long lifespan -

If I want to adjust the seat height, what should I keep in mind?

A heated seat or passenger seat cover may limit the choice of height adjustment.

With a padded upholstery, the seat surface is narrower. (The higher the padded upholstery, the narrower the seat).

With a low-padded upholstery, the seat is wider. (The lower the seat, the wider the surface).

In the least-padded upholstery, the seat height is reduced, but the crotch arch is shortened by the change in shape.

-

What happens during a foam replacement?

When we replace the foam in your seat, we remove part of the original foam and replace it with a harder composite foam.

-

Do you install heated seats?

No, we do not install heating into any seats. If you already have seat heating installed, your seat cannot be fitted with low-padding upholstery.

Please note: The seat heating will lose heating power with the installation of a padded upholstery or comfort cushioning. It is also not possible to replace the foam, because the original foam would have to be removed.

-

I have a passenger seat cover. Is that a problem?

We can customize your seat, even if you have a passenger seat cover. For reworking and optimal adjustment, we ask you to send the cover to us together with your seat.

-

You also order shape modifications. What does that mean?

You can choose between...

Standard shape = the original shape remains the same.

Racing shape = we customize the seat into a racing shape. The passenger area is largely eliminated by filling in and rounding off the rear area (possible but uncomfortable).

Touring shape = we customize the seat into a touring shape. This involves inserting a foam wedge. The wedge protects the passenger against slipping and offers a more secure grip while riding. The passenger is then also seated higher than the driver.

-

I am located in XY. Can I have my seat customized by SW-MOTECH?

-

Power supply

-

Sind die Electric Motorbike Adapters auch wasserdicht?

Produkte von SW-MOTECH zur Cockpit-Stromversorgung bestehen aus hochwertigen Komponenten, die sorgfältig für den Einsatz am Motorrad ausgewählt werden. Dabei achten wir neben langer Haltbarkeit auch auf den Schutz exponierter Bauteile vor Spritzwasser. Dazu kommen beispielsweise spritzwassergeschützte Abdeck-Kappen, Schalter-Abdeckungen oder Kabeldurchführungen zum Einsatz. Auch das verwendete Isolierungsmaterial hält Feuchtigkeit zuverlässig ab. Wir können aber keine vollständige Wasserdichtigkeit garantieren - dazu sind die Montage- und Verlegungsmöglichkeiten an den unterschiedlichen Fahrzeugen einfach zu vielfältig.

-

Sind die Electric Motorbike Adapters auch wasserdicht?